Call: 08071930866

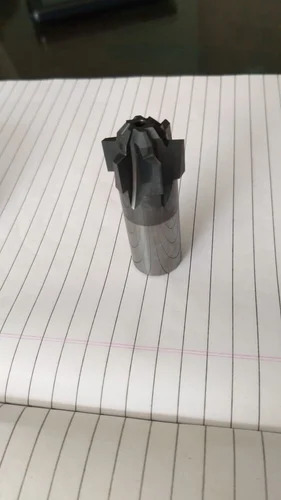

Best Ball Nose End Mills For 3D Contouring

Product Details:

- Surface Finish Polished

- Features Rust proof

- Usage Industrial

- Size Standard

- Material Carbide

- Color Silver

- Shape Round

- Click to View more

X

Best Ball Nose End Mills For 3D Contouring Price And Quantity

- 10 Piece

Best Ball Nose End Mills For 3D Contouring Product Specifications

- Industrial

- Silver

- Round

- Standard

- Polished

- Carbide

- Rust proof

Best Ball Nose End Mills For 3D Contouring Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 2-10 Days

- All India

Product Description

Experience the Astonishing performance of our Hot-selling Best Ball Nose End Mills For 3D Contouring! Manufactured from enlightened carbide material, these tools boast rust proof properties with a polished silver finish. Their towering efficiency stands out especially in industrial use, offering customers a true hot deal for precision applications. Featuring a round shape and standard sizes, this spotlight product is ideal for intricate 3D machining. As a trusted exporter, manufacturer, and supplier from India, we ensure every piece meets superior quality standards.

Unparalleled 3D Contouring Precision

Our Best Ball Nose End Mills for 3D Contouring are perfectly suited for industrial environments where fine 3D work is essential. These tools excel in mold-making, die-casting, and prototyping applications, providing smooth finishes on a variety of materials. Their primary competitive advantages include rust resistance, a polished appearance, and robust durability. Companies benefit from seamless integration into most CNC machines, securing enhanced productivity and reliability at job sites.

Reliable Export Markets and Shipping Assurance

We deliver our Best Ball Nose End Mills For 3D Contouring globally, serving prominent markets in Asia, Europe, and North America. Clients can quickly obtain a quotation, clear payment terms, and shipping logistics details. Our streamlined export process ensures timely shipped goods through reputable FOB ports across India, providing peace of mind and efficiency with every order. Dedicated support ensures customer satisfaction from dispatch to delivery.

Unparalleled 3D Contouring Precision

Our Best Ball Nose End Mills for 3D Contouring are perfectly suited for industrial environments where fine 3D work is essential. These tools excel in mold-making, die-casting, and prototyping applications, providing smooth finishes on a variety of materials. Their primary competitive advantages include rust resistance, a polished appearance, and robust durability. Companies benefit from seamless integration into most CNC machines, securing enhanced productivity and reliability at job sites.

Reliable Export Markets and Shipping Assurance

We deliver our Best Ball Nose End Mills For 3D Contouring globally, serving prominent markets in Asia, Europe, and North America. Clients can quickly obtain a quotation, clear payment terms, and shipping logistics details. Our streamlined export process ensures timely shipped goods through reputable FOB ports across India, providing peace of mind and efficiency with every order. Dedicated support ensures customer satisfaction from dispatch to delivery.

FAQs of Best Ball Nose End Mills For 3D Contouring:

Q: How are your Best Ball Nose End Mills suitable for industrial 3D contouring applications?

A: Our end mills are specifically designed for industrial-grade 3D contouring, allowing for unparalleled accuracy and smooth surface finishes in tasks such as mold-making and complex prototyping.Q: What materials are the ball nose end mills made from?

A: These end mills are crafted from premium carbide, ensuring exceptional durability, rust-proof performance, and a consistently polished finish.Q: Where can your ball nose end mills be applied?

A: They are ideal for use in CNC machining centers, mold-making, die-manufacturing, aerospace, and automobile component shapinganywhere precise 3D surface machining is required.Q: What is the typical process for ordering and shipping these end mills internationally?

A: Simply request a quotation, confirm payment terms, and well manage the shipment logistics. Goods are dispatched promptly via trusted FOB ports in India to your requested destination.Q: What benefits can customers expect from using your ball nose end mills?

A: Users benefit from improved workpiece quality, reduced machine downtime, and long-lasting tool performance, all while maintaining rust resistance and outstanding finish.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese