Call: 08071930866

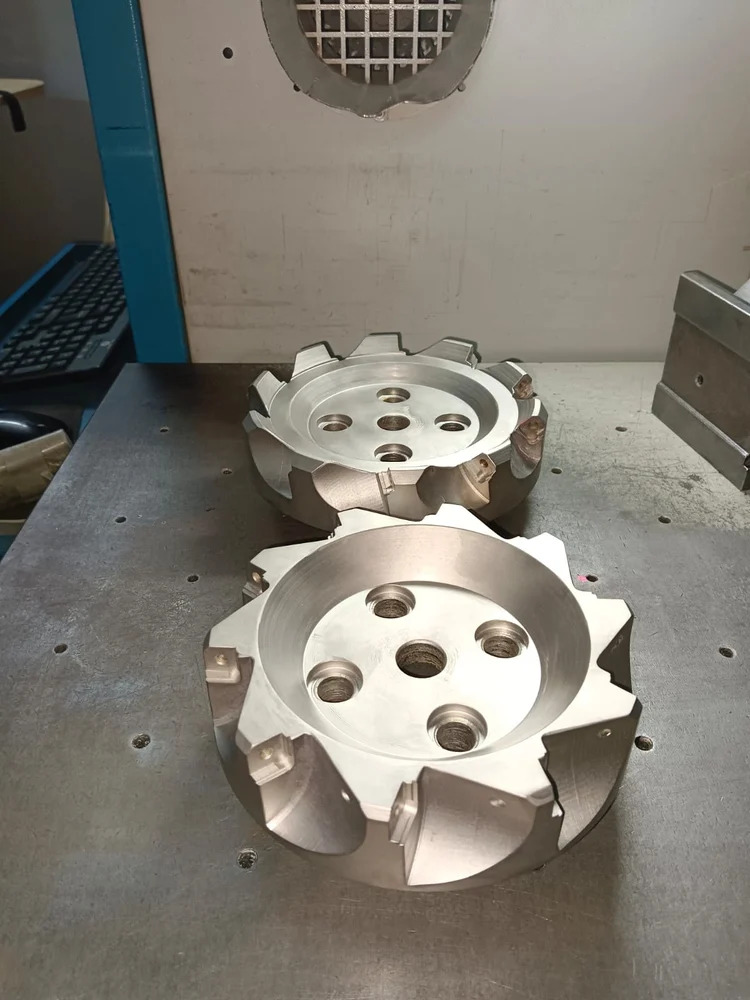

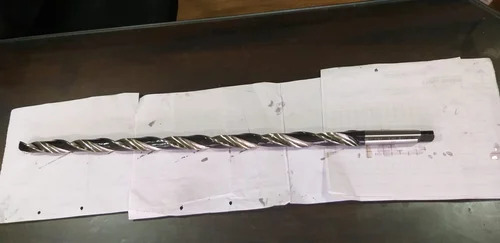

Mold and Die Machining Tools

2969 INR/Piece

Product Details:

X

Mold and Die Machining Tools Price And Quantity

- 6 Piece

- 2969 INR/Piece

Mold and Die Machining Tools Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 2-10 Days

- All India

Product Description

Experience superlative precision with our Mold and Die Machining Tools, expertly crafted for remarkable performance and reliability. Engineered from rarefied high-speed steel and carbide, these customizable tools feature a versatile cutting diameter range of 1 mm to 20 mm with both straight and tapered shank types. Their high hardness (HRC 60-68), polished finish, and advanced TiN or TiAlN coating guarantee exceptional wear and heat resistance, making them suitable for CNC machining centers and EDM machines. Benefit from reduced prices during our exclusive clearance event. Delivered in secure plastic box and carton packaging, these tools promise consistent results. Renowned as leading exporters, manufacturers, and suppliers from India.

Advantages and Applications of Mold and Die Machining Tools

Mold and Die Machining Tools offer rarefied accuracy in industrial processes, essential for mold and die making, as well as high-precision manufacturing plants. Their wear-resistant and heat-resistant features enable prolonged use in intensive CNC machining and EDM operations. These tools greatly increase productivity and output quality, making them indispensable across sectors like automotive, aerospace, and general engineering. Their adaptable design supports a wide range of plant applications with both custom and standard components.

Payment Terms, Sample Availability, and Delivery Information

Quotations for Mold and Die Machining Tools are tailored to your specific requirements, with attractive reduced prices on clearance lots. Samples are available to allow assessment prior to ordering. Upon confirmation, shipped goods are dispatched promptly, with secure shipping to guarantee safe arrival. Delivery times are optimized to meet industrial schedules, ensuring minimal downtime. Flexible payment options facilitate smooth transactions, making procurement straightforward and reliable for clients worldwide.

Advantages and Applications of Mold and Die Machining Tools

Mold and Die Machining Tools offer rarefied accuracy in industrial processes, essential for mold and die making, as well as high-precision manufacturing plants. Their wear-resistant and heat-resistant features enable prolonged use in intensive CNC machining and EDM operations. These tools greatly increase productivity and output quality, making them indispensable across sectors like automotive, aerospace, and general engineering. Their adaptable design supports a wide range of plant applications with both custom and standard components.

Payment Terms, Sample Availability, and Delivery Information

Quotations for Mold and Die Machining Tools are tailored to your specific requirements, with attractive reduced prices on clearance lots. Samples are available to allow assessment prior to ordering. Upon confirmation, shipped goods are dispatched promptly, with secure shipping to guarantee safe arrival. Delivery times are optimized to meet industrial schedules, ensuring minimal downtime. Flexible payment options facilitate smooth transactions, making procurement straightforward and reliable for clients worldwide.

FAQs of Mold and Die Machining Tools:

Q: How can I customize the Mold and Die Machining Tools to fit my specific requirements?

A: You can specify your desired cutting diameter, shank type, and coating preference during the inquiry process. Our team will assist you in tailoring the tools to your exact industrial or plant application needs.Q: What materials are used in these machining tools and what are their benefits?

A: These tools are manufactured from high-speed steel and carbide, noted for their durability and heat resistance. This ensures long service life and consistently precise results in mold and die operations.Q: When can I expect the delivery of my ordered tools after placing a quotation?

A: Once your order is confirmed, we initiate secure shipping promptly. Most orders are delivered within the stipulated timeframe mentioned in your quotation, ensuring reliable and timely supply for your operations.Q: Where are these Mold and Die Machining Tools typically used?

A: They are widely utilized in CNC machining centers, EDM machines, and various industrial sectors including mold and die manufacturing, automotive, and engineering plants requiring high precision and durability.Q: What are the benefits of the advanced coatings like TiN and TiAlN on these tools?

A: TiN and TiAlN coatings greatly enhance wear resistance, extend tool life, and provide superior heat resistance, resulting in improved machining efficiency and surface finish quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese