Call: 08071930866

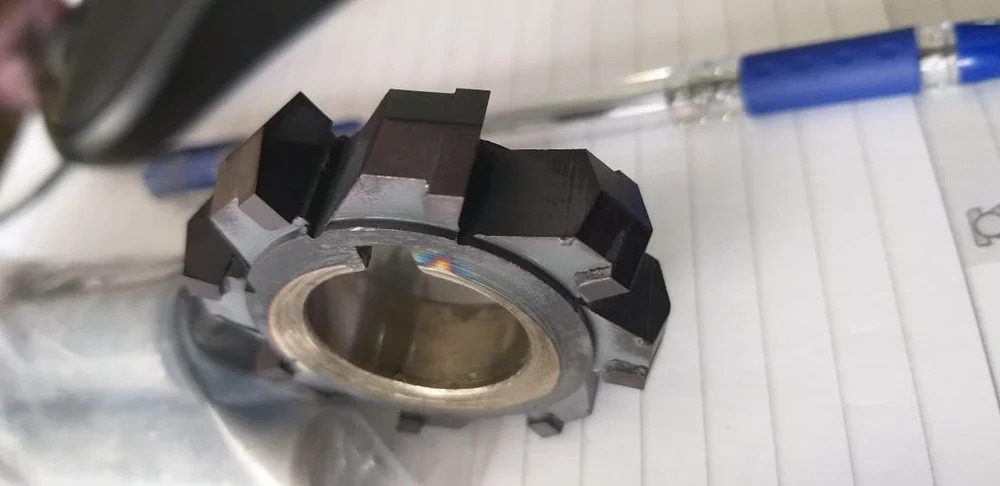

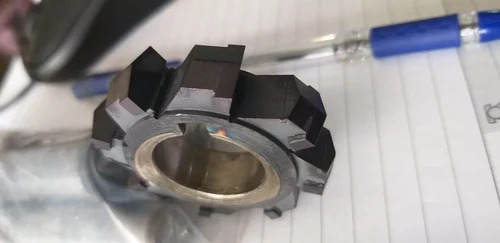

Side And Face Milling Cutter.

2500 INR/Piece

Product Details:

- Material solid carbide,brazed carbide & HSS

- Shape Round

- Hardness Upto 60 HRC

- Features High quality

- Size upto 40mm Bore Size

- Diameter upto 150 Millimeter (mm)

- Color Silver

- Click to View more

X

Side And Face Milling Cutter. Price And Quantity

- 1 Piece

- 2500 INR/Piece

Side And Face Milling Cutter. Product Specifications

- upto 150 Millimeter (mm)

- High quality

- upto 40mm Bore Size

- Upto 60 HRC

- Silver

- solid carbide,brazed carbide & HSS

- Round

Side And Face Milling Cutter. Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 2-10 Days

- All India

Product Description

Get your hands on our hot-selling Side And Face Milling Cutter, meticulously crafted in a top-ranking silver finish. Engineered from solid carbide, brazed carbide, and unmatchable HSS, this praiseworthy tool is designed for exceptional results. Offered in round shape with a diameter up to 150 mm and bore size up to 40 mm, it assures reduced wear thanks to its impressive hardness up to 60 HRC. As a leading exporter, manufacturer, and supplier from India, we deliver high-quality products tailored to precision machining requirements worldwide.

Exclusive Features and Advantages

Discover the unwavering reliability of Side And Face Milling Cutters, boasting high quality and round shape for optimized cutting precision. The tools extraordinary hardness, up to 60 HRC, guarantees enduring durability and minimal maintenance. With material selection ranging from solid carbide to HSS, users enjoy substantial operational advantages, including improved cutting speeds and reduced processing times. The diverse diameter options make it adaptable for a variety of milling tasks, enhancing productivity across manufacturing sectors.

Packaging, Delivery, and Sample Offerings

Each Side And Face Milling Cutter is carefully packed to prevent any damage during transit, reflecting our commitment to quality. Delivery time is prompt, ensuring customers receive their products without significant waiting. We provide sample availability so you can assess the product before committing your expenditure. The list price reflects the superior craftsmanship, and special offers may be available for bulk ordershelping you optimize investment for your tooling needs.

Exclusive Features and Advantages

Discover the unwavering reliability of Side And Face Milling Cutters, boasting high quality and round shape for optimized cutting precision. The tools extraordinary hardness, up to 60 HRC, guarantees enduring durability and minimal maintenance. With material selection ranging from solid carbide to HSS, users enjoy substantial operational advantages, including improved cutting speeds and reduced processing times. The diverse diameter options make it adaptable for a variety of milling tasks, enhancing productivity across manufacturing sectors.

Packaging, Delivery, and Sample Offerings

Each Side And Face Milling Cutter is carefully packed to prevent any damage during transit, reflecting our commitment to quality. Delivery time is prompt, ensuring customers receive their products without significant waiting. We provide sample availability so you can assess the product before committing your expenditure. The list price reflects the superior craftsmanship, and special offers may be available for bulk ordershelping you optimize investment for your tooling needs.

FAQs of Side And Face Milling Cutter.:

Q: How is the Side And Face Milling Cutter used in machining operations?

A: The Side And Face Milling Cutter is primarily used for cutting slots and grooves, as well as for face and side milling in both manual and CNC machines, thanks to its robust construction and compatibility with various setups.Q: What materials are available for the Side And Face Milling Cutter?

A: These cutters come in solid carbide, brazed carbide, and HSS, each chosen for their durability and performance in different machining applications, enabling customers to select the material best suited to their needs.Q: When can customers expect delivery after placing an order?

A: Orders are processed efficiently, with prompt delivery times to ensure that customers minimize downtime and receive their cutters in a timely manner.Q: Where is the Side And Face Milling Cutter manufactured and exported from?

A: Our Side And Face Milling Cutters are manufactured, supplied, and exported from India, reaching clients across the globe through an efficient logistics network.Q: What is the process for obtaining a sample of the milling cutter?

A: Customers may request a sample by contacting our sales team; upon approval, a sample will be dispatched, allowing users to evaluate the tools performance before making a full purchase.Q: How does the high hardness of the cutter benefit users in machining?

A: The cutters high hardness, up to 60 HRC, ensures excellent wear resistance and prolonged service life, especially during rigorous milling processes, leading to unmatchable operational efficiency and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese