Call: 08071930866

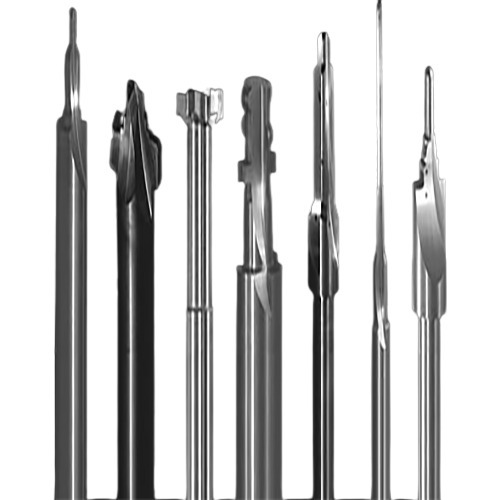

Solid Carbide Ball Nose End Mill Cutter

Product Details:

- Hardness Rigid

- Features High Quality

- Size Various

- Weight Differ as per size Kilograms (kg)

- Color Silver

- Click to View more

X

Solid Carbide Ball Nose End Mill Cutter Price And Quantity

- 10 Unit

Solid Carbide Ball Nose End Mill Cutter Product Specifications

- Silver

- Various

- Differ as per size Kilograms (kg)

- High Quality

- Rigid

Solid Carbide Ball Nose End Mill Cutter Trade Information

- 5000 Unit Per Month

- 7 Days

- All India

Product Description

Redeem machining excellence with our Solid Carbide Ball Nose End Mill Cutter, offered at a special rate to top your industrial requirements. Manufactured in India by an incomparable exporter, manufacturer, and supplier, this sublime product features a rigid, high-quality build in a striking silver finish. Available in various sizes, weights vary accordingly to assure optimal fit for every need. The transcendent performance makes it ideal for demanding applications, delivering precise results and unbeatable durability that stand out in modern industrial tooling environments.

Exceptional Features & Versatile Applications

The Solid Carbide Ball Nose End Mill Cutter exhibits high quality and sublime rigidity, engineered for unbeatable accuracy. It excels across diverse machine setupsapplicable in milling, profiling, and finishing operations. Manufacturers, engineers, and workshops regularly deploy these cutters on CNC machines, vertical mills, and automated production lines, ensuring transcendent performance and durability in every use.

Packing, Dispatch, and Supply Logistics

Meticulous packing & dispatch processes guarantee the safety of each cutter during transit, minimizing unnecessary expenditure. The cutters are shipped from major Indian ports under competitive FOB rates tailored for exporters, suppliers, and global buyers. With an impressive supply ability, the manufacturer ensures steady availability and prompt dispatch, catering to market needs without compromise.

Exceptional Features & Versatile Applications

The Solid Carbide Ball Nose End Mill Cutter exhibits high quality and sublime rigidity, engineered for unbeatable accuracy. It excels across diverse machine setupsapplicable in milling, profiling, and finishing operations. Manufacturers, engineers, and workshops regularly deploy these cutters on CNC machines, vertical mills, and automated production lines, ensuring transcendent performance and durability in every use.

Packing, Dispatch, and Supply Logistics

Meticulous packing & dispatch processes guarantee the safety of each cutter during transit, minimizing unnecessary expenditure. The cutters are shipped from major Indian ports under competitive FOB rates tailored for exporters, suppliers, and global buyers. With an impressive supply ability, the manufacturer ensures steady availability and prompt dispatch, catering to market needs without compromise.

FAQs of Solid Carbide Ball Nose End Mill Cutter:

Q: How is the Solid Carbide Ball Nose End Mill Cutter utilized in machining applications?

A: This cutter is frequently employed for precision milling, contouring, and finishing tasks on CNC machines, providing smooth and accurate results due to its sublime hardness and design.Q: What sizes and weights are available for these end mill cutters?

A: The cutters come in various sizes, with the weight differing according to each specific dimension. This allows users to select an optimal tool tailored for their machining requirements.Q: Where are the cutters primarily exported or supplied from?

A: Manufactured in India, these high-quality cutters are exported and supplied from major industrial hubs and shipping ports, catering to both domestic and international clientele.Q: What is the typical packaging process before dispatch?

A: Each cutter undergoes secure packing procedures involving rigorous checks to ensure protection and safe transit, thus reducing expenditure on potential damages during shipment.Q: When should operators choose this ball nose end mill cutter over alternatives?

A: Operators should redeem the advantages of these cutters for tasks requiring incomparably smooth finishes or demanding profiles, especially where rigidity and longevity are paramount.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese