Call: 08071930866

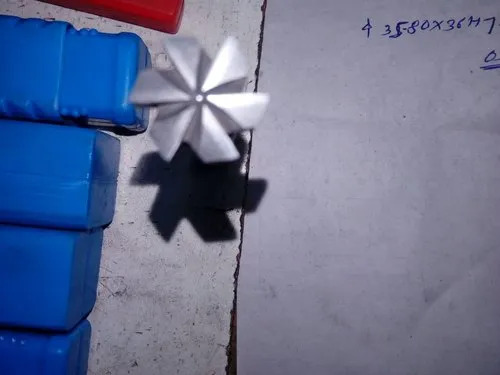

Solid Carbide End Mills

996 INR/Piece

Product Details:

- Shape Round

- Features Durable

- Material Carbide

- Usage Industrial

- Size 70 mm Length Of Cut

- Diameter 32 Millimeter (mm)

- Click to View more

X

Solid Carbide End Mills Price And Quantity

- 10 Piece

- 996 INR/Piece

Solid Carbide End Mills Product Specifications

- 70 mm Length Of Cut

- Carbide

- Round

- Industrial

- 32 Millimeter (mm)

- Durable

Solid Carbide End Mills Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 2-10 Days

- All India

Product Description

Experience world-class precision with our Solid Carbide End Mills, expertly shaped round and designed for optimum performance. With a rare 70 mm length of cut and a robust diameter of 32 mm, these end mills offer unmatched durability for industrial applications. As a leading exporter, manufacturer, and supplier from India, we guarantee a lavish finish and reduced tool wear. Get industry-standard carbide material ensuring longevity, resilience, and superior cutting speeds. Make your machining process seamless and efficient with these premium tools, crafted for professionals who demand excellence.

Commercial Applications and Usage Method

Solid Carbide End Mills are essential for varied industrial machining tasks, including milling, slotting, and contouring. Their optimum 32 mm diameter ensures precision on metallic surfaces such as steel, aluminum, and cast iron. To use, mount the end mill onto CNC or manual milling equipment following recommended operational settings for speed and feed. The durable carbide material ensures reduced chipping and stable performance, making them indispensable in factories and workshops.

Packing & Dispatch Details and Sample Policy

Each Solid Carbide End Mill is meticulously packed for security during dispatching, ensuring the product remains undamaged throughout shipment. Packing & Dispatch procedures comply with robust industry standards before being shipped across India and worldwide. Samples are available for prospective clients to inspect quality and fit prior to larger orders. Our transparent sample policy assures clients satisfaction, enabling well-informed purchasing decisions before dispatching bulk shipments.

Commercial Applications and Usage Method

Solid Carbide End Mills are essential for varied industrial machining tasks, including milling, slotting, and contouring. Their optimum 32 mm diameter ensures precision on metallic surfaces such as steel, aluminum, and cast iron. To use, mount the end mill onto CNC or manual milling equipment following recommended operational settings for speed and feed. The durable carbide material ensures reduced chipping and stable performance, making them indispensable in factories and workshops.

Packing & Dispatch Details and Sample Policy

Each Solid Carbide End Mill is meticulously packed for security during dispatching, ensuring the product remains undamaged throughout shipment. Packing & Dispatch procedures comply with robust industry standards before being shipped across India and worldwide. Samples are available for prospective clients to inspect quality and fit prior to larger orders. Our transparent sample policy assures clients satisfaction, enabling well-informed purchasing decisions before dispatching bulk shipments.

FAQs of Solid Carbide End Mills:

Q: How are Solid Carbide End Mills packaged for shipping?

A: Solid Carbide End Mills are securely packed in protective cases or boxes to prevent damage, with all dispatching and shipping processes adhering to strict safety standards.Q: What commercial benefits do Solid Carbide End Mills offer?

A: These end mills deliver reduced tool wear, world-class precision, and optimum durability, resulting in efficient machining, lower operational costs, and lavish finishes on industrial components.Q: Where can Solid Carbide End Mills be applied?

A: They are suitable for use on a variety of metallic surfaces in industries such as automotive, aerospace, and manufacturing, ensuring versatility in commercial machining.Q: What is the process of procuring samples of the product?

A: Prospective buyers may request samples, which are shipped upon verifying policy compliance, allowing inspection and testing before large-scale procurement.Q: When is the best time to use these end mills?

A: Use Solid Carbide End Mills for tasks requiring precise cutting, rigorous durability, and high-speed performance, particularly during demanding industrial machining operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese