Call: 08071930866

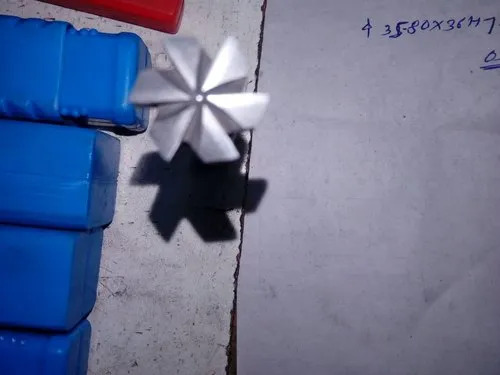

Tapered End Mills For Mold Making

1269 INR/Piece

Product Details:

- Material Carbide

- Features High quality

- Usage Industrial

- Shape Round

- Size Standard

- Color Silver

- Click to View more

X

Tapered End Mills For Mold Making Price And Quantity

- 1269 INR/Piece

- 10 Piece

Tapered End Mills For Mold Making Product Specifications

- Round

- Industrial

- Silver

- High quality

- Standard

- Carbide

Tapered End Mills For Mold Making Trade Information

- Cash in Advance (CID)

- 1000 Piece Per Month

- 2-10 Days

- All India

Product Description

Discover our ephemeral yet commanding range of Tapered End Mills for Mold Making, meticulously crafted in India. Manufactured from gilt-edged carbide material, these round, silver end mills guarantee enduring crackerjack quality fit for the most demanding industrial applications. As a popular exporter, manufacturer, and supplier, we offer these high-performance tools at a reduced price, ensuring exceptional value. Their standard size and superior features enhance precision and efficiency for mold making specialists, blending durability with a professional finish you can trust, project after project.

Versatile Performance Across Industrial Media

Tapered End Mills for Mold Making excel across a range of media such as metals, plastics, and composites. Designed for smooth operation, their features include high hardness, thermal stability, and reduced wearcritical for extended machine runs. Frequently applied in automotive, aerospace, and die-making industries, these end mills are invaluable for detailed mold shaping, cavity cutting, and complex profiling, ensuring reliability and efficiency for professional machinists in demanding environments.

Expansive Export Networks and Reliable Delivery Solutions

Our main export markets encompass Europe, North America, and Southeast Asia, with a commanding presence in Indias domestic sector. Packing & Dispatch procedures ensure each shipment is meticulously handled, minimizing expenditure and supporting a seamless supply chain. Our robust supply ability meets large-scale demands, providing timely delivery to distributors and end-users. Clients can trust our expertise in coordinating shipments efficiently, making us a preferred supplier for both domestic and international markets.

Versatile Performance Across Industrial Media

Tapered End Mills for Mold Making excel across a range of media such as metals, plastics, and composites. Designed for smooth operation, their features include high hardness, thermal stability, and reduced wearcritical for extended machine runs. Frequently applied in automotive, aerospace, and die-making industries, these end mills are invaluable for detailed mold shaping, cavity cutting, and complex profiling, ensuring reliability and efficiency for professional machinists in demanding environments.

Expansive Export Networks and Reliable Delivery Solutions

Our main export markets encompass Europe, North America, and Southeast Asia, with a commanding presence in Indias domestic sector. Packing & Dispatch procedures ensure each shipment is meticulously handled, minimizing expenditure and supporting a seamless supply chain. Our robust supply ability meets large-scale demands, providing timely delivery to distributors and end-users. Clients can trust our expertise in coordinating shipments efficiently, making us a preferred supplier for both domestic and international markets.

FAQs of Tapered End Mills For Mold Making:

Q: How are Tapered End Mills for Mold Making utilized in industrial settings?

A: These end mills are employed primarily for mold shaping, cavity cutting, and contouring tasks in sectors such as automotive, aerospace, and die-making, thanks to their durable carbide material and high precision design.Q: What is the process for ordering and shipment of these end mills?

A: Clients can place orders directly through our website or authorized distributors. Each order undergoes careful packing & dispatch, followed by swift shipment, ensuring prompt and safe delivery worldwide.Q: Where are your main export markets and can you supply large orders?

A: We export mainly to Europe, North America, and Southeast Asia, and maintain a commanding presence in India. With robust production capabilities, we efficiently meet both bulk and standard-sized orders.Q: What are the key benefits of the reduced price offering?

A: A reduced price makes our high-quality, crackerjack carbide end mills more accessibledelivering professional performance without inflating your expenditure, while still upholding gilt-edged standards of manufacturing.Q: What features distinguish these Tapered End Mills for Mold Making?

A: High-quality carbide construction, silver finish, standard sizing, and reliable resistance to wear and heat make these end mills exceptional for detailed industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese